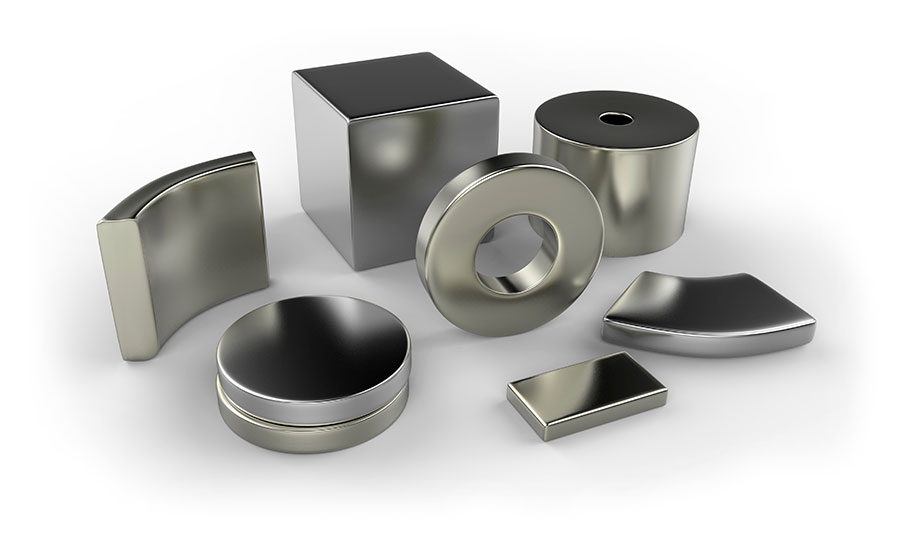

Sintered & Cast Magnets

The sintering process involves compacting fine powders at high pressure in an aligning magnetic field, then sintering into solid shape. After sintering, the magnet shape is rough, and will need to be machined to achieve close tolerances. The complexity of shapes that can be thus pressed is limited.

Sintered Rare Earth magnets from NdFeB or SmCo are Anisotropic and the strongest magnets on the market today.

Sintered magnet manufacturing process

Sintered magnets are produced through a powder metallurgy process where fine magnetic powders are compacted under high pressure in an aligning magnetic field. The compacted material is then sintered at high temperature, forming a dense and solid magnet. After sintering, the magnet shape is relatively rough and typically requires machining to achieve close dimensional tolerances. Due to the pressing process, the achievable geometry is more limited compared to molded magnet technologies.

Magnetic performance and material strength

Sintered rare earth magnets such as NdFeB and SmCo are anisotropic and represent the strongest magnets available on the market today. These materials are commonly used in applications where maximum magnetic performance is required, such as electric motors, generators and high-efficiency drive systems.

Rare earth free magnet alternatives

In many applications, a rare earth free magnet is a preferred solution. Materials such as ferrite and AlNiCo do not rely on rare earth elements and offer stable, predictable magnetic properties. Choosing a rare earth free magnet can reduce dependency on volatile raw material markets while providing reliable performance over long service life.

A rare earth free magnet is particularly suitable for applications exposed to high temperatures or where thermal stability is critical. Ferrite magnets are widely used in PM motor rotors and industrial equipment, while AlNiCo magnets are often selected for sensor and electromechanical applications due to their excellent temperature resistance.

Selecting the right sintered magnet

Sura Magnets supports customers in selecting the optimal sintered magnet material based on performance requirements, operating conditions and cost targets. Whether the application requires maximum magnetic strength or a robust rare earth free magnet, each solution is engineered to ensure long-term reliability and consistent performance.